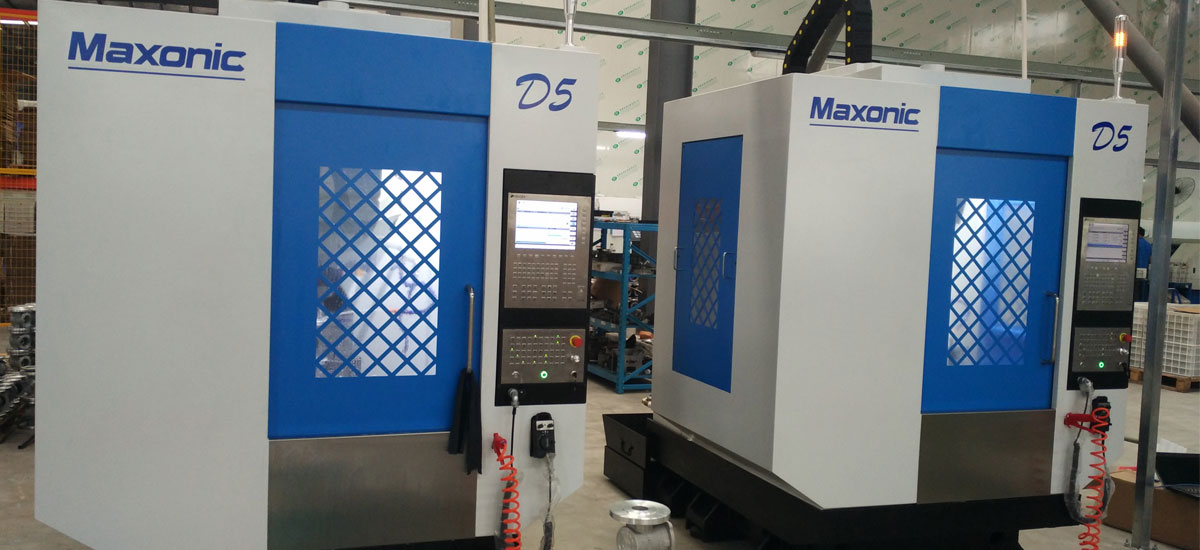

We are pleased to announce the completion of the development of a 3D milling machine together with our Chinese sales partner. After extensive testing of the prototypes the release of a first series of 300 pieces was approved. The challenge was to offer a price-optimized alternative to industry standards without sacrificing functionality and quality. Thanks to our constantly optimized development software VECTOSTUDIO, the project was completed within 18 months.

Technical specifications

- eightfold field weakened asynchronous spindle with a speed of 24,000 rpm

- Power X / Y / Z servo inverter: 7.5 kW

- Power spindle inverter: 22 kW

- Acceleration X / Y / Z: 12/10/7 m / s²

- Max. Speed: 0.8 m / s

The milling machine features HSC (High Speed Cutting), leadscrew pitch compensation with zero backlash compensation, threading with C and Z axis interpolation and can process NC files according to the current ISO standard (ISO 66025). In the interests of a higher processing speed, a maximum configurable allowable deviation can be determined by reducing the set amount from the original file. Another optimization of the milling path is the “ContourLookAhead function”, which enables improved acceleration profiles. By modifying the acceleration ramps during processing, a real-time analysis is used to reduce the machine`s vibration by a factor up to ten. This causes an active vibration suppression, which not only improves the milling pattern but also results in a longer machine life. In addition to the software module mentioned, the technology developed by ARADEX in the milling machine also covers the power electronics, the bus system and the control system. Due to the great demand for industrial drive technology in China, more industrial projects will be implemented in China – for example the development of a punching machine has already been initiated.