Product has been added for comparison.

Voltage range:

Continous power:

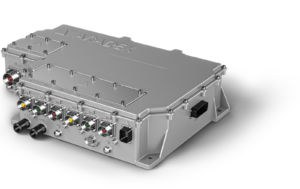

The main function of an inverter is to generate a 3-phase AC voltage from a DC voltage for driving e-motors. With the VECTOPOWER family, we also place high value on a second function: perfect integration into an overall high-voltage system with all the possible interactions. The synergetic combination of FPGA control and integrated high-speed PLC function of the VECTPOWER provides the perfect platform to achieve this. Our inverters match perfectly together with our VP5000 DC/DC converters.

Series3 of our VP600 mobile inverters includes the SafeTorqueOff function according to DIN61800-5-2 PL-D cat 3.

This allows the use of ARADEX function modules and the development of your own functions, directly in the inverter.

Our software tools for diagnostics and parameterization provide you with optimum support for commissioning and optimization.

Unfortunately we could not find any results for your search. Please

try another search or contact us.

To implement drive functions, it is often advantageous to connect a drive control unit (DCU) between the vehicle control unit (VCU) and the inverter or inverters. Functions with short reaction times can be implemented in this drive control. For example synchronization processes for shiftable gearboxes. VECTOPOWER offers you this functionality without additional hardware as an integrated control, directly in the inverter. Freely programmable and in 500µs real time. And you can also implement functions for neighboring inverters in one inverter.

VECTOPOWER inverters support different motor topologies and offer numerous parameterizable operating modes. Depending on the device version we also offer solutions for high-speed motors up to 1999Hz. An advantage is the “on-the-fly” switchability of operating modes and parameters without interrupting operation. With switchable PWM frequency and control parameters within 0.5ms we achieve higher starting torques for example.

Integrated commissioning, analyzing, development and diagnostics tools. Explore our available tools.

Regardless of whether you want to reduce the wear on expensive special tires with reduced slip or optimize the shifting process in shiftable transmissions with robust claw coupling through extremely dynamic synchronization processes: With the integrated real-time PLC functionality, you or we can realize this directly in the inverter. And you save an additional drive control unit (DCU).

Our VirtualSensorTechnology enables various additional functions in the operation of ship propellers. We are thinking here of the detection and suppression of disruptive cavitation or highly redundant parallel hybrids.

Our VirtualSensorTechnology enables diagnostic insights into the functions of the combustion engine without additional sensors. The torque curves of the individual cylinders can be observed and compared in order to detect irregularities in time and possibly optimize maintenance intervals.

Lifting loads gently but quickly? Detect and reduce pitching vibrations of a boom by lifting a load? Detect irregularities when winding up the winch? We don’t have any patent solutions for this. But with VirtualSensorTechnology and the integrated high-speed PLC in our VECTOPOWER inverters, we offer you high-performance tools. for your functions and your USPs.

With VirtualSensorTechnology, we make torques of electric motors estimable quickly and with high resolution. Combine this with your know-how for special pumps in order to monitor or control viscosity in real time for example. Or for “advanced functions” in hydraulic systems via the electrically driven pump.

From conceptual design and project planning to commissioning and after-sales business, we deliver the system components as well as powerful tools and customized functions to find the best solution for your application.

If you do not find the right motor in our portfolio or you have found a motor from other manufacturers that is optimal for your application: You have our support! For this purpose, we can validate your motor with our VECTOPOWER inverter on our drive test bench. We determine the optimal parameters and create the overall characteristic diagrams of the motor with inverter as drive unit for you.