Product has been added for comparison.

Voltage range:

Continous power:

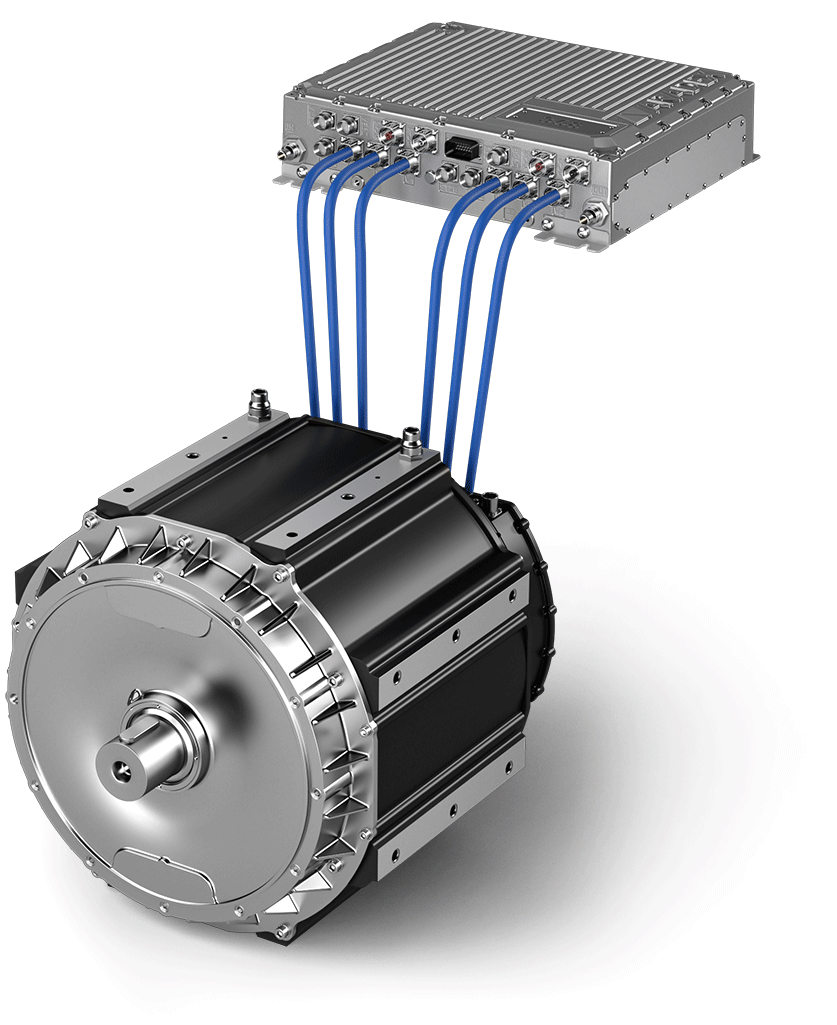

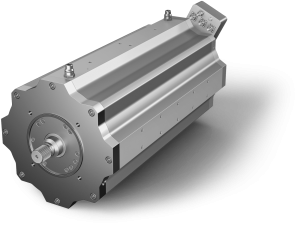

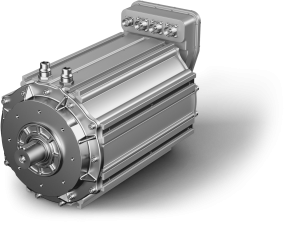

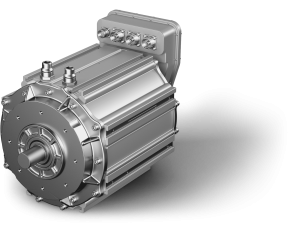

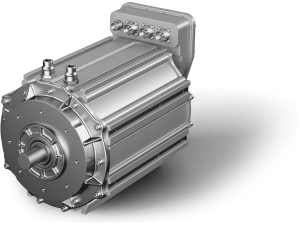

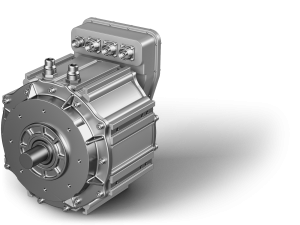

ARADEX offers you complete units of inverter + motor + optional gearbox. The inverters have matching parameter maps. But even if our motors do not cover your requirements, we offer you the advantage of system solutions: On our in-house test benches, we can calibrate and optimize the motor you have selected with the VECTOPOWER inverter. Including the system maps of power and efficiency.

On our in-house test rigs. For optimum efficiency and power yield.

VP600 inverters cover a wide voltage range and adapt to the current DC voltage in real time by parameter transformation.

On our test benches we parameterize the VECTOPOWER inverter optimally for your desired e-motor.

Unfortunately we could not find any results for your search. Please

try another search or contact us.

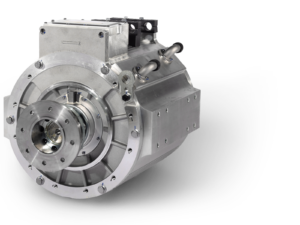

Depending on the application, we recommend drives directly on the cardan shaft or coupled via gearboxes. We offer both solutions and can thus find the optimum solution for your project.

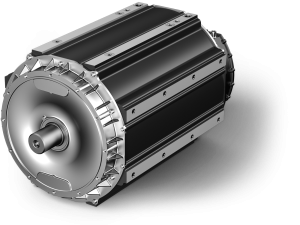

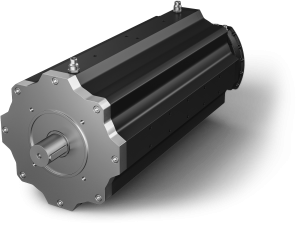

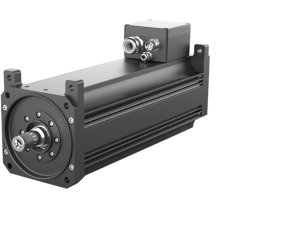

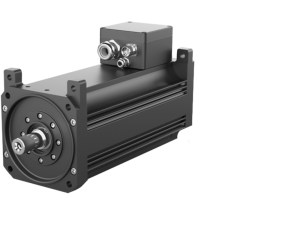

We have deliberately developed solutions for both PM reluctance motors and magnet-free asynchronous motors. Each of these topologies offers specific characteristics that are advantageous depending on the application. VECTOPOWER supports both topologies and can be adapted by parameter sets.

All parameters relevant for the efficiency of the system are created in the VETOPOWER inverter as 2D maps. These are determined on our in-house test benches and adapt automatically and in real time, to a changing supply voltage, for example. Thus, we achieve best values in efficiency and in the available power of the drives.

Due to their function, all inverters limit the current and thus the possible torque at low speeds and especially at standstill. Through a very flexible adaptation of the internal switching frequencies (additional technology module required), we achieve high torques even from zero speed.

In the inverters as well as in the e-motors, different components can be found in different time constants with regard to overload capability. Through detailed system knowledge, we make these overload capacities profitable for your application, without risking damage to the inverters or motors. These calculable and thus available overload reserves often allow smaller, lighter and cheaper overall solutions.

You can’t find the ideal e-motor in our portfolio? But you want the advantage of a system? No problem! We are able to measure motors of other manufacturers on our test benches together with the selected VECTOPOWER inverter and to determine the optimal parameter sets. And you will also then receive the complete results in the form of characteristic diagrams for efficiency, torque and power.

Here we offer technology modules as functions in the drive inverter to reduce slippage and thus tire wear, for example. Or also to improve drivability.

With our VirtualSensor technology, we aim to gain insight into the rolling behavior of drive chains, to adjust the chain tension ideally or to detect wear.

In addition to sensitive control of the propeller speed, VirtualSensor also allows you to evaluate the torque of the propeller in real time. For example to prevent cavitation or to quickly detect grounding.

VirtualSensor can provide valuable services here by sensitively measuring the drive torque without the need for additional sensors. This applies to both the winding and unwinding of the rope as well as the detection and evaluation of the coupled load.

Electrified hydraulics can offer advantatages by replacing a fixed-speed hydraulic pump (diesel engine) with variable displacement by an efficient solution of inverter + e-motor + fixed-displacement hydraulic pump. VirtualSensor then provides additional advantages through fast and sensitive determination of the drive torques of the hydraulics.

Swiveling movements, milling, drilling, cutting….? Let us analyze your application together and find the best solution.

From conceptual design and project planning to commissioning and after Sales maintenance, we deliver the system components as well as powerful tools and customized functions to ensure the best performance for your application.