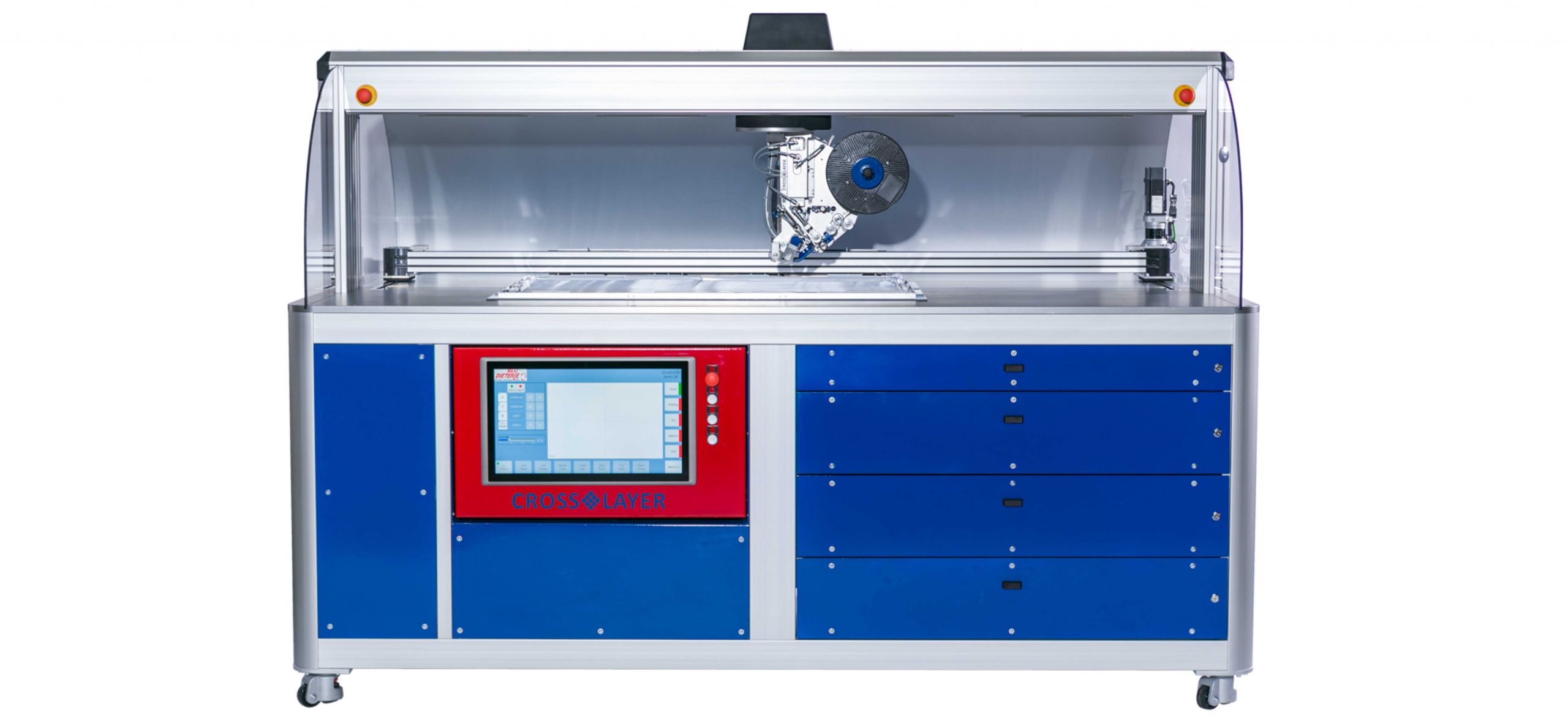

For the newly developed tape laying machine from M & A Dieterle from the Swabian town of Ottenbach, ARADEX AG supplied the development of the software as well as the machine control. The project is a machine for laying textile carbon fiber tapes. The tapes are stored fully automated in any geometry, orientation, and length and then stored as a textile pattern. The semi-finished product is called a preform. The valuable carbon fibers are so placed that as little waste is produced as possible thus minimising the material requirements. An important aspect in the layout of the controller was the ease of use of the system. By tracing three geometric shapes (rectangle, rhombus and circle) all possible shapes can be designed. Adjustable parameters are angle, distance, position and laying speed. The shapes can then be assembled into a design. The preform or the scrim is placed on a movable hoop. This can be removed from the machine for subsequent embroidering of local reinforcement elements and then integrated into an embroidery machine. In the next process step, the 2D preforms are converted into 3D components and cured with resin. The CROSSLAYER tape laying machines thus enable individual and stable preform production with less material usage. The process is used in a very wide range of products, the production of lightweight bicycle saddles and skateboards are only two of many possible applications. For the success of the project, ARADEX contributed the software in the form of the HMI VECTOVISION and the machine control VD-Control. Thus, in addition to the regulation of work processes, an application-optimized user interface with additional functions could be implemented. The training phase for the customer is short, the user interface intuitive. The prototype of the machine named Crosslayer was presented at the JEC World in Paris in the spring of 2019: The machine can be tested in Ottenbach at the company M & A Dieterle and is now available. For more informations click here.

Back